Throttle control systems play a crucial role in modern vehicles and machinery, ensuring optimal performance and efficiency. Among various models available, the K25LP throttle control stands out due to its advanced features and reliability. This guide will provide a comprehensive understanding of K25LP throttle control, covering its functionality, advantages, installation procedures, and maintenance tips. Whether you’re an automotive enthusiast or a professional technician, this article will equip you with all the information you need about K25LP throttle control.

Introduction to K25LP Throttle Control

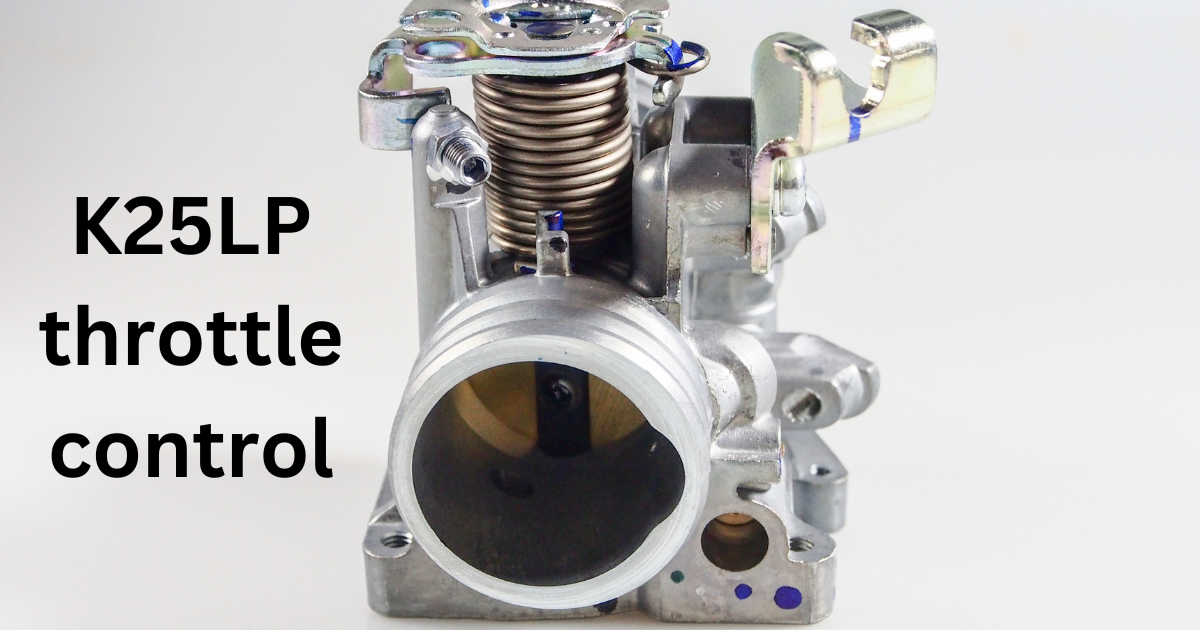

The K25LP throttle control is an advanced system designed to manage the engine’s airflow efficiently, ensuring that the vehicle or machinery operates at peak performance. Throttle control systems are integral to both internal combustion engines and electric vehicles, allowing for precise control over acceleration and deceleration. In essence, the throttle controls the amount of air entering the engine, which in turn regulates the engine’s power output.

What sets the K25LP apart from other throttle control systems is its sophisticated design and cutting-edge technology. This model is engineered to provide improved responsiveness, making it ideal for a wide range of applications, from industrial machinery to high-performance vehicles. Understanding the capabilities and benefits of K25LP throttle control is essential for anyone looking to optimize their engine’s performance and efficiency.

Understanding the Basics of Throttle Control

Throttle control refers to the mechanism that regulates the amount of air or fuel entering the engine. In an internal combustion engine, the throttle valve opens and closes to control airflow, which directly influences engine power and efficiency. As the driver presses the accelerator pedal, the throttle control system responds by adjusting the throttle valve position, allowing more air into the engine to increase power output. Conversely, releasing the pedal reduces airflow, resulting in deceleration.

In recent years, electronic throttle control (ETC) has gained popularity due to its numerous advantages over traditional mechanical systems. The K25LP throttle control is a prime example of ETC technology, utilizing sensors and electronic signals to achieve precise control over throttle position. This advanced technology not only enhances engine performance but also contributes to improved fuel efficiency and reduced emissions, making it a crucial component in modern vehicles and machinery.

Key Features of the K25LP Throttle Control

The K25LP throttle control boasts a variety of features designed to enhance performance and reliability. One of its most notable attributes is its electronic control mechanism, which utilizes advanced sensors to monitor throttle position and respond instantly to driver input. This allows for smoother acceleration and deceleration, improving overall driving experience and comfort.

Additionally, the K25LP is equipped with a fail-safe mechanism that ensures safe operation even in the event of a malfunction. This feature is particularly important for heavy machinery and vehicles operating in challenging conditions, where safety is paramount. The K25LP’s durable construction and weather-resistant components also contribute to its longevity, making it a reliable choice for various applications.

The intuitive design of the K25LP throttle control makes it easy to install and integrate with existing systems. Its compatibility with a range of vehicles and machinery further enhances its appeal, providing users with flexibility and convenience. Overall, the K25LP throttle control combines advanced technology with practical features, making it an ideal solution for anyone looking to improve their vehicle or machinery performance.

Advantages of the K25LP Throttle Control

One of the primary advantages of the K25LP throttle control is its enhanced precision and responsiveness. Traditional mechanical throttle systems often suffer from delays in response time, which can lead to less efficient acceleration and deceleration. In contrast, the K25LP utilizes electronic sensors to deliver instantaneous feedback, resulting in smoother and more controlled power delivery. This precision not only enhances driving comfort but also improves overall vehicle safety, particularly during high-speed maneuvers or emergency situations.

Furthermore, the K25LP throttle control contributes to improved fuel efficiency. By regulating the air intake more accurately, it ensures that the engine operates optimally under varying conditions. This can lead to significant savings on fuel costs over time, making the K25LP an economical choice for both personal and commercial use. Additionally, the K25LP’s advanced technology reduces emissions, aligning with modern environmental standards and regulations.

Another advantage of the K25LP throttle control is its versatility. It can be used in a wide range of applications, from passenger vehicles to heavy industrial machinery. This adaptability makes it a preferred choice among automotive enthusiasts and professionals alike. By investing in K25LP throttle control, users can enjoy a host of benefits, including improved performance, enhanced safety, and cost savings.

How K25LP Throttle Control Enhances Vehicle Performance

The K25LP throttle control significantly enhances vehicle performance by providing more precise control over engine output. With its electronic design, the K25LP can quickly adjust the throttle position based on driver inputs, optimizing acceleration and deceleration. This responsiveness is especially beneficial during rapid maneuvers, where instant power delivery is crucial for maintaining control.

Moreover, the K25LP throttle control contributes to better fuel economy. By accurately regulating the air-fuel mixture, it ensures that the engine operates at its most efficient level, reducing unnecessary fuel consumption. This is particularly advantageous for drivers who frequently traverse hilly terrains or engage in stop-and-go traffic, as the K25LP can adapt to changing conditions seamlessly.

In addition to enhancing performance, the K25LP throttle control helps to reduce wear and tear on engine components. By providing smoother power delivery and minimizing abrupt changes in throttle position, it lessens the strain on the engine and related systems. This not only prolongs the life of the vehicle but also reduces maintenance costs over time. Overall, the K25LP throttle control is an essential component for anyone seeking to maximize their vehicle’s performance and efficiency.

K25LP Throttle Control Applications

The versatility of the K25LP throttle control makes it suitable for a wide array of applications across different industries. In the automotive sector, it is commonly used in both passenger vehicles and commercial trucks, enhancing performance and fuel efficiency. Many automotive enthusiasts and professional tuners choose the K25LP for its ability to deliver precise control, making it ideal for performance upgrades.

In addition to automotive applications, the K25LP throttle control is also employed in industrial machinery. Equipment such as forklifts, excavators, and other heavy machinery benefits from the K25LP’s robust performance characteristics, allowing operators to maintain better control over power delivery in demanding environments. This is crucial in construction and manufacturing, where precision and efficiency are paramount for productivity.

Marine vehicles also utilize K25LP throttle control systems, where reliable performance is essential for safe navigation. In these applications, the K25LP ensures smooth acceleration and deceleration, enabling operators to handle vessels more effectively. The adaptability of the K25LP throttle control to various environments and requirements highlights its significance as a valuable component across multiple industries.

Key Components of K25LP Throttle Control

Understanding the key components of the K25LP throttle control system is essential for both installation and maintenance. The primary component is the throttle lever, which is typically connected to the accelerator pedal. When the driver presses the pedal, the throttle lever adjusts the throttle position to control airflow into the engine.

Another critical component is the electronic control module (ECM), which interprets input signals from various sensors and determines the appropriate throttle position. The K25LP utilizes advanced sensors to monitor factors such as engine speed, load, and temperature, enabling it to make real-time adjustments for optimal performance.

Additionally, the wiring and connectors used in the K25LP throttle control system play a vital role in ensuring reliable communication between components. High-quality wiring and secure connections are necessary to prevent signal interference and ensure accurate performance. Overall, a solid understanding of these key components is essential for anyone working with the K25LP throttle control system, whether for installation, maintenance, or troubleshooting purposes.

How to Select the Right K25LP Throttle Control for Your Needs

When it comes to selecting the right K25LP throttle control for your specific needs, there are several factors to consider. First and foremost, it’s essential to assess the specifications of your vehicle or machinery. The K25LP throttle control is compatible with a range of engine types and sizes, so it’s crucial to verify that the model you choose aligns with your requirements. Check the manufacturer’s guidelines and consult with experts if needed to ensure compatibility.

Next, consider the application for which you’ll be using the throttle control. Different applications, such as automotive racing or industrial machinery, may require specific features. For example, if you’re looking for enhanced responsiveness for racing, prioritize models with advanced electronic control features. On the other hand, if your primary concern is durability in industrial settings, focus on options that offer weather resistance and robust construction.

Lastly, evaluate your budget. While the K25LP throttle control is a valuable investment, prices can vary based on features and specifications. Compare different models and consider long-term benefits, such as fuel savings and reduced maintenance costs, to determine the best value for your needs. By carefully considering these factors, you can select the right K25LP throttle control that suits your specific applications and performance requirements.

Installation of K25LP Throttle Control: Step-by-Step Guide

Installing the K25LP throttle control can be a straightforward process if approached methodically. Before beginning, ensure you have all necessary tools and materials, such as a screwdriver, wiring connectors, and the K25LP throttle control unit. Make sure to consult the manufacturer’s instructions for specific guidelines tailored to your vehicle or machinery.

Step 1: Disconnect Power

Begin by disconnecting the vehicle’s battery to prevent any electrical hazards during installation. This is a critical safety measure to ensure that no current flows through the system while you’re working.

Step 2: Remove the Old Throttle Control

Locate the existing throttle control unit and disconnect it from the wiring harness. Carefully remove any mounting screws or clips that secure the old unit, and take note of how everything is connected for reference during the installation of the K25LP.

Step 3: Install the K25LP Throttle Control

Position the K25LP throttle control in the same location as the old unit. Secure it in place using the provided screws or clips, ensuring a tight fit to avoid vibration during operation. Connect the wiring harness according to the specifications provided in the installation guide, making sure that all connections are secure and properly insulated.

Step 4: Reconnect Power and Test

Once the K25LP throttle control is installed, reconnect the vehicle’s battery. Start the engine and allow it to idle for a few moments before testing the throttle response. Gently press the accelerator pedal to ensure that the K25LP is functioning correctly. If everything operates smoothly, you have successfully installed your new throttle control system.

By following these steps, you can ensure a successful installation of the K25LP throttle control, enhancing the performance and efficiency of your vehicle or machinery.

Also Read: Zhuoxin Data Technology Leadership

Wiring Diagrams and Electrical Connections for K25LP Throttle Control

Proper wiring is crucial for the effective operation of the K25LP throttle control. Understanding the wiring diagram can greatly simplify the installation process and help troubleshoot any issues that may arise. The K25LP typically includes several wires: power, ground, and signal wires connected to various sensors and the electronic control module.

Basic Wiring Instructions

- Power Wire: This wire connects the K25LP to the vehicle’s battery or power source. Ensure that the connection is secure and properly insulated to prevent shorts.

- Ground Wire: The ground wire is equally essential for proper function. Connect it to the vehicle’s chassis or designated ground point, ensuring a solid connection.

- Signal Wires: These wires connect the throttle control to the engine’s sensors and the ECM. Each wire serves a specific function, so refer to the wiring diagram provided by the manufacturer to ensure accurate connections.

Common Mistakes to Avoid

- Neglecting Ground Connections: A loose or corroded ground connection can lead to erratic behavior or complete system failure.

- Inadequate Insulation: Ensure all connections are adequately insulated to prevent electrical interference and shorts.

- Ignoring Manufacturer’s Guidelines: Always refer to the manufacturer’s wiring diagram for the most accurate installation procedure.

By following these wiring guidelines, you can ensure that your K25LP throttle control operates effectively and reliably.

Programming and Calibrating K25LP Throttle Control

After installing the K25LP throttle control, programming and calibration are essential steps to ensure optimal performance. Proper programming allows the throttle control system to adapt to your specific vehicle’s engine characteristics, leading to improved throttle response and overall efficiency.

How to Program Settings for Optimal Performance

- Access the Control Module: Using a compatible diagnostic tool, connect to the K25LP’s control module. This tool will allow you to enter programming mode and access the various settings.

- Adjust Throttle Position Settings: Follow the prompts on the diagnostic tool to adjust throttle position settings based on your vehicle’s specifications. This process typically involves calibrating the idle position and full throttle position to ensure accurate response.

- Save and Exit: Once the settings are adjusted, save your changes and exit programming mode. It’s essential to verify that the new settings have been applied correctly before proceeding.

Calibrating the Throttle Response

Calibration is a crucial step that ensures the throttle control system accurately reflects driver input. This process involves:

- Testing Throttle Response: After programming, conduct a series of tests by pressing the accelerator pedal and observing how the engine responds. Adjustments may be needed based on your observations.

- Revisiting Settings: If the throttle response feels sluggish or unresponsive, revisit the programming tool and fine-tune the settings until you achieve the desired response.

By carefully programming and calibrating your K25LP throttle control, you can ensure that it operates at peak performance, providing you with an optimal driving experience.

How to Test and Validate K25LP Throttle Control After Installation

Testing the K25LP throttle control after installation is essential to ensure it functions correctly. A thorough validation process can help identify any potential issues and ensure that the system operates as intended. Here’s a step-by-step guide to testing and validating your K25LP throttle control:

Step 1: Initial Visual Inspection

Begin with a visual inspection of the installed throttle control. Check all connections to ensure they are secure and properly insulated. Look for any signs of wear or damage on the wiring and components, as these can lead to operational issues.

Step 2: Perform a Functionality Test

With the vehicle running, conduct a functionality test. Gradually press the accelerator pedal and observe the throttle response. The engine should respond smoothly and promptly to your input, without any hesitation or stalling. If the throttle feels unresponsive or erratic, it may indicate a problem that needs to be addressed.

Step 3: Monitor Engine Performance

While driving the vehicle, pay attention to engine performance. Take note of how well the engine accelerates and decelerates in various conditions. If you experience any irregularities, such as stalling, loss of power, or inconsistent acceleration, further investigation may be necessary.

Step 4: Use Diagnostic Tools

For a more in-depth analysis, utilize a diagnostic tool to read any error codes from the control module. This tool can provide valuable insights into potential issues and help you pinpoint any necessary adjustments or repairs.

By conducting these tests and validations, you can ensure that your K25LP throttle control is operating correctly and efficiently, allowing for a safer and more enjoyable driving experience.

Maintenance Tips for K25LP Throttle Control

Regular maintenance is key to ensuring the longevity and reliability of your K25LP throttle control. By following a consistent maintenance routine, you can prevent potential issues and keep your throttle control system functioning optimally. Here are some essential maintenance tips to consider:

Regular Cleaning and Inspection

Periodically clean the throttle control unit and surrounding areas to remove dirt, debris, and contaminants that may affect performance. Use a soft cloth and non-corrosive cleaner to gently wipe down the throttle body and surrounding components. Additionally, inspect wiring connections for signs of wear, corrosion, or loose connections.

Monitor Performance Metrics

Keep an eye on performance metrics such as fuel efficiency and throttle response. Sudden changes in these metrics may indicate a problem with the throttle control system. If you notice any irregularities, conduct a thorough inspection or consult a professional technician for assistance.

Update Software and Firmware

If your K25LP throttle control system includes software or firmware, be sure to check for updates regularly. Manufacturers often release updates that enhance performance, address bugs, or improve compatibility with newer engine systems. Following these updates can significantly impact the effectiveness of your throttle control.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s maintenance guidelines for specific recommendations tailored to your K25LP throttle control model. Adhering to these guidelines ensures that you perform the correct maintenance procedures at appropriate intervals, prolonging the lifespan of your system.

By implementing these maintenance tips, you can enhance the reliability and efficiency of your K25LP throttle control, ensuring it remains in optimal condition for years to come.

Troubleshooting K25LP Throttle Control Issues

Despite its robust design and advanced technology, issues may arise with the K25LP throttle control system over time. Knowing how to troubleshoot common problems can save you time and prevent further damage to your vehicle or machinery. Here are some common issues you may encounter and their corresponding solutions:

Unresponsive Throttle

If the throttle does not respond when you press the accelerator pedal, start by checking the wiring connections. Loose or corroded connections can prevent signals from reaching the control module. Ensure that all connections are secure and free of debris. If the wiring appears intact, use a diagnostic tool to check for error codes that may indicate a malfunctioning sensor or component.

Erratic Throttle Response

An erratic throttle response can be caused by various factors, including sensor malfunctions or calibration issues. Begin by inspecting the throttle position sensor for any signs of damage or wear. If necessary, recalibrate the throttle control system using the diagnostic tool. Ensure that the programming settings align with your vehicle’s specifications for optimal performance.

Engine Stalling or Hesitation

If your engine stalls or hesitates during acceleration, it may be due to an incorrect air-fuel mixture. This issue can often be resolved by recalibrating the throttle control settings. Additionally, inspect the air intake system for blockages or leaks that may affect airflow. If problems persist, consider consulting a professional technician for a comprehensive diagnosis.

By familiarizing yourself with these common troubleshooting techniques, you can address issues with your K25LP throttle control quickly and effectively, minimizing downtime and ensuring a safe driving experience.

The Importance of Software Updates for K25LP Throttle Control

In today’s technologically advanced world, software updates play a critical role in maintaining the performance and efficiency of electronic systems, including the K25LP throttle control. Regular updates can enhance functionality, improve compatibility with newer engine systems, and fix any bugs or vulnerabilities. Here’s why keeping your K25LP throttle control software up to date is essential:

Enhanced Performance

Software updates often include enhancements that improve the overall performance of the throttle control system. These improvements may optimize throttle response, increase fuel efficiency, or address any issues reported by users. By regularly updating the software, you can ensure that your K25LP throttle control operates at its best, providing you with a smoother and more responsive driving experience.

Increased Safety

Updates frequently address safety concerns by fixing bugs or vulnerabilities that may compromise system integrity. This is particularly important for throttle control systems, as even minor glitches can lead to significant safety issues. By keeping your K25LP throttle control software updated, you can minimize the risk of malfunctions and ensure a safer driving experience.

Compatibility with New Technology

As automotive technology continues to evolve, it’s crucial to ensure that your throttle control system remains compatible with newer engines and electronic components. Software updates can improve compatibility and performance, allowing the K25LP throttle control to integrate seamlessly with the latest advancements in automotive technology.

To stay informed about available updates, regularly check the manufacturer’s website or consult your vehicle’s service manual. By prioritizing software updates, you can enhance the functionality and reliability of your K25LP throttle control system.

Comparing K25LP Throttle Control with Other Models

When considering throttle control systems, it’s important to understand how the K25LP compares to other available models. Various throttle control systems offer unique features and benefits, making it essential to evaluate your options before making a decision. Here’s a comparison of the K25LP throttle control with other common throttle control models:

K25LP vs. Traditional Mechanical Throttle Control

Traditional mechanical throttle control systems rely on a cable connected to the accelerator pedal to regulate airflow. While these systems are simple and cost-effective, they often lack the precision and responsiveness of electronic throttle control (ETC) systems like the K25LP. The K25LP offers smoother acceleration, better fuel efficiency, and improved safety features, making it a superior choice for modern vehicles.

K25LP vs. Competing Electronic Throttle Control Systems

When compared to other ETC systems, the K25LP throttle control stands out due to its advanced features and versatility. While many competing systems offer similar electronic controls, the K25LP is known for its reliability and ease of installation. Additionally, it is compatible with a wide range of vehicles and machinery, making it a flexible choice for various applications.

Performance Considerations

In terms of performance, the K25LP throttle control excels in providing precise control over engine output. While some competing models may offer specific advantages in niche applications, the K25LP delivers a well-rounded performance that caters to diverse needs. Its superior responsiveness, fuel efficiency, and durability make it an attractive option for both automotive enthusiasts and professionals.

By comparing the K25LP throttle control with other models, you can make an informed decision that aligns with your performance requirements and application needs.

User Experiences and Testimonials on K25LP Throttle Control

User experiences and testimonials can provide valuable insights into the performance and reliability of the K25LP throttle control. Many users report significant improvements in vehicle performance after installing the K25LP, citing enhanced responsiveness and smoother acceleration. Here are some common themes reflected in user testimonials:

Enhanced Performance

Numerous users highlight the noticeable difference in throttle response after installing the K25LP throttle control. Many report that the vehicle feels more powerful and agile, particularly during acceleration. This improved performance contributes to a more enjoyable driving experience, making the K25LP a popular choice among automotive enthusiasts.

Improved Fuel Efficiency

A common sentiment among users is the enhanced fuel efficiency achieved with the K25LP throttle control. Many drivers note that they can achieve better mileage, particularly in city driving conditions. This improvement not only saves money on fuel costs but also aligns with eco-friendly driving practices, making the K25LP an appealing option for environmentally conscious consumers.

Reliability and Durability

Users consistently praise the K25LP for its reliability and robust construction. Many have reported using the throttle control in challenging conditions, such as off-road driving or heavy industrial applications, without experiencing any issues. This reliability, combined with ease of installation, makes the K25LP throttle control a favorite among both professionals and casual users alike.

By considering user experiences and testimonials, you can gain valuable insights into the K25LP throttle control’s performance, reliability, and overall effectiveness, helping you make an informed decision.

Future Trends in Throttle Control Technology

As technology continues to evolve, the future of throttle control systems is expected to witness significant advancements. These trends aim to enhance performance, safety, and efficiency in vehicles and machinery. Here are some of the anticipated trends in throttle control technology, particularly concerning systems like the K25LP:

Increased Integration with Advanced Driver Assistance Systems (ADAS)

Future throttle control systems are likely to integrate more seamlessly with advanced driver assistance systems (ADAS). This integration will enable features such as adaptive cruise control and automated acceleration, enhancing overall driving safety and convenience. As vehicles become more autonomous, the role of throttle control in supporting these systems will be critical.

Enhanced Data Analytics and Real-Time Monitoring

The future of throttle control technology will likely see an increase in data analytics capabilities. By utilizing real-time data from various sensors, throttle control systems can optimize performance based on driving conditions. This level of monitoring can provide drivers with valuable insights into vehicle performance, allowing for proactive maintenance and more informed driving decisions.

Focus on Sustainability and Emission Reductions

With growing concerns about environmental sustainability, future throttle control systems will prioritize fuel efficiency and emission reductions. Innovations in electronic throttle control technology will contribute to cleaner engine operation, aligning with stricter regulations on emissions. This focus on sustainability will drive the development of advanced throttle control systems that deliver exceptional performance while minimizing environmental impact.

By keeping an eye on these trends, you can stay informed about the future of throttle control technology and how systems like the K25LP will continue to evolve.

Conclusion

Investing in the K25LP throttle control system is a strategic decision for anyone looking to enhance vehicle performance and efficiency. With its advanced electronic control technology, the K25LP offers precise throttle response, improved fuel efficiency, and superior reliability compared to traditional mechanical systems. Whether you are a professional technician, an automotive enthusiast, or an operator of industrial machinery, the K25LP throttle control provides the performance enhancements needed to achieve optimal results.

In addition to its performance benefits, the K25LP throttle control is versatile and adaptable, making it suitable for a wide range of applications across various industries. Its ease of installation, coupled with comprehensive maintenance support, ensures that users can enjoy the advantages of the K25LP without unnecessary complications.

Furthermore, the K25LP’s commitment to innovation and reliability positions it as a frontrunner in throttle control technology. By prioritizing features such as real-time monitoring and integration with advanced systems, the K25LP is designed to meet the evolving needs of modern vehicles and machinery.

In conclusion, the K25LP throttle control is a smart investment for anyone seeking to optimize their engine’s performance and efficiency. With its advanced features, reliability, and versatility, it stands out as a top choice in the competitive throttle control market.

FAQs

What is the K25LP throttle control?

The K25LP throttle control is an advanced electronic throttle control system designed to regulate engine airflow efficiently. It enhances vehicle performance, responsiveness, and fuel efficiency compared to traditional mechanical throttle systems.

How do I install the K25LP throttle control?

Installation of the K25LP throttle control involves disconnecting the vehicle’s battery, removing the old throttle control unit, installing the K25LP, and reconnecting the battery. Detailed steps can be found in the installation section of this article.

How do I troubleshoot issues with the K25LP throttle control?

Common troubleshooting steps for K25LP throttle control issues include checking wiring connections, inspecting the throttle position sensor, and using diagnostic tools to read error codes. Refer to the troubleshooting section of this article for more detailed guidance.